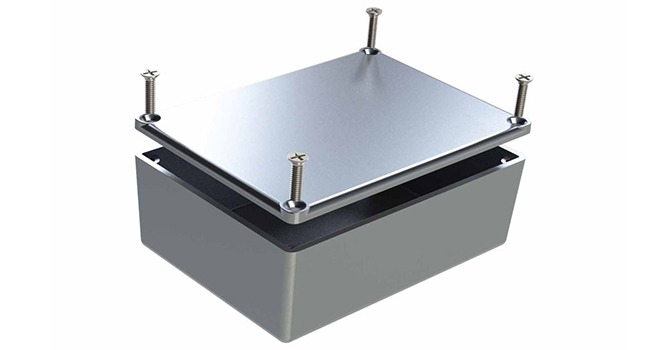

The selection of enclosure material is pivotal for electronic housings, impacting device durability and performance. Aluminum enclosures for electronics have become increasingly popular this year, let’s delve into three key aspects that highlight why aluminum enclosures are a preferred choice for electronics:

Why Electronics Need Housings

Electronic housings fulfill crucial roles in enhancing electronics, ensuring performance, safety, and longevity. Here are key reasons why these enclosures are essential:

Protection: Safeguarding components from external elements like dust and moisture, electronic housings maintain the reliability of sensitive circuits.

Safety: By containing components effectively, electronic housings reduce risks of shock, overheating, and fire hazards.

User Experience: Serving as a physical interface for interaction, well-designed electronic housings enhance usability and comfort for users.

Aesthetics: The visual appeal of electronic devices is significantly influenced by sleek and well-designed housings, making products more appealing to consumers.

- Thermal Management: Properly designed electronic housings facilitate heat dissipation, ensuring components operate within optimal temperature ranges, thereby enhancing device performance and longevity.

How do housings impact the thermal management of electronic devices?

Housings play a significant role in the thermal management of electronics by affecting heat dissipation, temperature regulation, and overall performance. Here are several ways in which housings impact the thermal management of electronics:

Heat Dissipation

Housings can either facilitate or hinder the dissipation of heat generated by electronic components. Materials with high thermal conductivity, such as aluminum, can help transfer heat away from components more efficiently, preventing overheating and ensuring optimal operating temperatures.

Heat Trapping

Inadequate ventilation or poor design of the housing can trap heat inside the device, leading to thermal issues. Properly designed housings include features like vents, heat sinks, or fans to promote airflow and dissipate heat effectively.

Thermal Expansion

Housings made from materials with different coefficients of thermal expansion than the internal components can cause stress and potential damage due to temperature variations. Proper selection of housing materials that match the expansion rates of internal components can mitigate these issues.

Insulation

Electronic housings, like aluminum enclosures for electronics, also provide insulation, which can help maintain stable operating temperatures by protecting components from external temperature fluctuations. Insulating housings can prevent heat loss in cold environments or prevent heat gain in high-temperature environments.

What's The Advantage Of Aluminum

Aluminum’s unique properties make it an excellent choice for electronic enclosures, due to the following specific advantages:

Thermal Management

The high thermal conductivity of aluminum extrusions allows for efficient heat dissipation, crucial for maintaining safe operating temperatures within electronic devices and preventing thermal issues that can affect performance.

EMI/RFI Shielding

Aluminum’s natural ability to block electromagnetic interference (EMI) and radio frequency interference (RFI) helps protect sensitive electronic components from external signals, ensuring the integrity of data transmission and reception.

Corrosion Resistance

Aluminum’s inherent resistance to corrosion makes it well-suited for enclosures that may be exposed to moisture or harsh environmental conditions, guaranteeing long-term durability and protection for electronic systems.

Lightweight Strength

The lightweight yet robust nature of aluminum extrusions provides structural integrity without adding unnecessary weight, making it ideal for portable electronic devices or applications where weight is a concern.

Design Flexibility

Aluminum extrusions, especially aluminum enclosures for electronics, offer versatility in design, allowing for the creation of custom shapes and profiles tailored to specific electronic enclosure requirements, enabling efficient integration of components and optimizing space utilization.

Why Choose Aluminum Enclosures For Electronics

Aluminum enclosures, especially those crafted through extrusion processes, emerge as the premier choice for electronic applications owing to their seamless integration with the diverse heights of electronic components and the exceptional uniformity characteristic of extruded aluminum electronic enclosures.

Tailored Fit

The innate properties of aluminum perfectly align with the demands of electronic enclosures, adeptly accommodating the varied heights of electronic elements with precision and efficiency within extruded aluminum electronic enclosures.

Precision in Extrusion

Extruded aluminum electronic enclosures epitomize uniformity in both design and construction, guaranteeing meticulous attention to detail in dimensions and ensuring a consistent standard of excellence across the entirety of the enclosure framework. This precision not only enhances the aesthetic appeal of the extruded aluminum electronic enclosures but also plays a pivotal role in maintaining the structural integrity necessary for safeguarding sensitive electronic components effectively.

Ease of Assembly

The precision and consistency of extruded aluminum enclosures significantly streamline the assembly process in electronic manufacturing. Their accurately extruded profiles and standardized dimensions allow for seamless integration of components, reducing the need for extensive modifications or adjustments during assembly. This precision not only cuts down on production time but also minimizes errors, ensuring a smoother workflow. Workers can efficiently fit electronic elements into the enclosures with precision, leading to faster production cycles and enhanced overall productivity in electronic device manufacturing processes.

Versatile Finishing Options

Aluminum allows for a wide range of finishing options, such as anodizing or powder coating, to enhance aesthetics and provide additional protection against wear and tear.