The HVAC&R sector extensively relies on aluminum heat exchanger. Why is aluminum the preferred choice in this industry? Let us, as professional aluminum product manufacturers, demonstrate the reasons behind its popularity and effectiveness in heat exchanger applications.

What Is Heat Exchanger

A heat exchanger is a device designed to efficiently transfer heat from one medium to another. It is commonly used in various industrial, residential, and commercial applications to either heat or cool fluids or gases. Heat exchangers work by allowing the transfer of thermal energy between two or more fluids at different temperatures without the fluids mixing. This transfer can be achieved through conduction, convection, or radiation, depending on the design of the heat exchanger. Heat exchangers are essential components in systems such as HVAC units, refrigeration systems, power plants, and chemical processing plants, where the efficient exchange of heat is crucial for optimal operation.

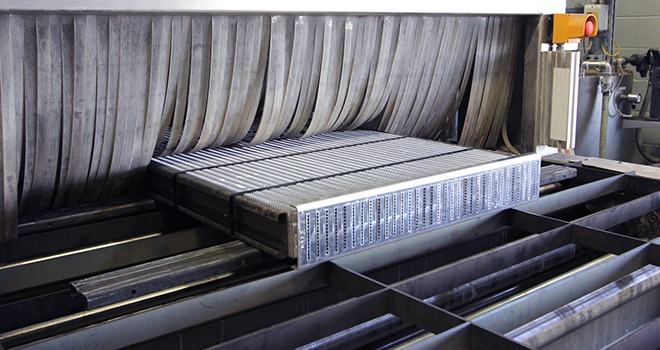

Aluminum Heat Exchanger Working Principle

The fundamental principle of an aluminum heat exchanger involves maximizing heat dissipation efficiency for rapid temperature reduction. This design enhances the pressure-bearing capacity of the aluminum plate-fin heat exchanger while promoting turbulent liquid flow to minimize sediment formation and enable a self-cleaning mechanism. Gaskets strategically seal the plates, preventing fluid leakage and directing the cold and hot liquids through their designated channels according to the system’s design specifications.

Is Aluminum Good For Heat Transfer?

To determine if aluminum is effective for heat transfer, key details about the metal are crucial. These include the heat transfer coefficient for aluminum, its applicable temperature range, and the density of aluminum. By understanding these fundamental aspects, we can evaluate whether aluminum is well-suited for efficient heat transfer applications.

Heat Transfer Coefficient For Aluminum

The heat transfer coefficient for aluminum typically ranges from 200 to 250 W/(m²·K) at room temperature. This value can vary based on factors such as the specific alloy, surface conditions, and temperature differentials.

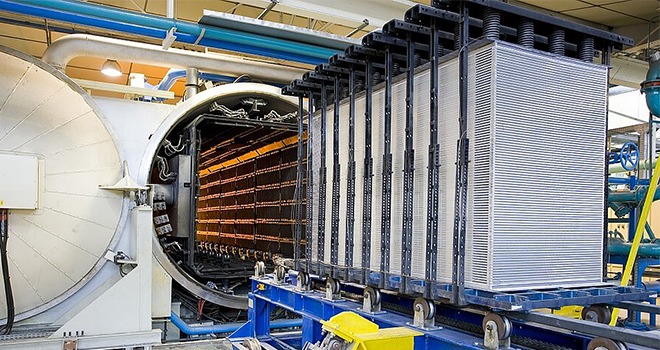

Aluminum Applicable Temperature Range

The applicable temperature range for aluminum typically extends from around -270°C to 660°C (-454°F to 1220°F). This range can vary depending on the specific alloy and the application in which the aluminum is being used. Aluminum demonstrates good thermal stability within this temperature range, making it suitable for a wide variety of heat transfer and other industrial processes.

Aluminum Density

The density of aluminum is approximately 2.70 grams per cubic centimeter (g/cm³). This relatively low density contributes to the lightweight nature of aluminum, making it a favorable material for various applications where weight reduction is important.

The Advantage Of Aluminum Heat Exchanger

Aluminum heat exchangers offer several advantages over other materials, primarily due to the unique properties of aluminum:

High Thermal Conductivity

Aluminum’s excellent thermal conductivity allows for efficient heat transfer within heat exchangers. This property enables rapid dissipation of heat, leading to improved performance and energy efficiency.

Quick Heat Transfer Response

Due to its high thermal conductivity, aluminum heat exchangers exhibit quick response times in transferring heat, making them ideal for applications where rapid temperature changes are required.

Optimal Heat Dissipation

Aluminum’s ability to dissipate heat effectively helps prevent overheating in systems, enhancing the overall reliability and lifespan of equipment utilizing aluminum heat exchangers.

Compact Design

Aluminum’s lightweight nature and high strength-to-weight ratio allow for the design of compact heat exchangers that can be easily integrated into space-constrained environments, maximizing efficiency in tight spaces.

What Is The Best Aluminum For Heat Exchanger

When it comes to the construction of aluminum heat exchangers, the choice of aluminum grade in specific positions is crucial for optimal performance. Different grades offer unique advantages based on their properties.

Aluminum Grades in Different Positions

- Core Tubes: 3003 aluminum is commonly used for core tubes due to its good formability and corrosion resistance.

- Fins: 1100 aluminum is preferred for fins as it offers excellent thermal conductivity and is easily formable.

- Headers: 6061 aluminum is often chosen for headers due to its good balance of strength and weldability.

Advantages of Different Aluminum Grades

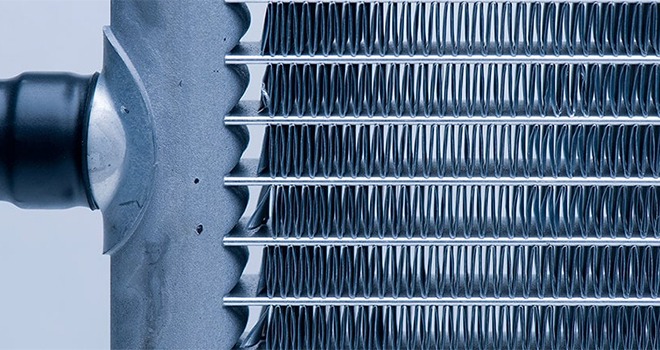

In the domain of aluminum heat exchangers, each component plays a distinct and vital role in ensuring efficient heat transfer:

The core tube, typically crafted from aluminum alloy 3003, acts as a conduit for the heat exchange fluid, enabling the transfer of thermal energy to or from the surrounding environment. The formability and corrosion resistance of 3003 aluminum are essential attributes that ensure the core tube can be shaped optimally to enhance fluid flow and withstand environmental degradation over time.

The fin, often composed of 1100 aluminum, is designed to amplify the surface area available for heat exchange. By expanding the area for thermal interaction between the fluid inside the tube and the ambient air or surrounding fluid, the fin boosts the efficiency of heat dissipation. The high thermal conductivity and formability of 1100 aluminum are key factors that contribute to the enhanced heat transfer capabilities of the fin.

The header, typically made from 6061 aluminum, acts as a pivotal connection point within the heat exchanger system. It manages the entry and exit of the heat transfer medium, directing its flow through the system. The strength, weldability, and machinability of 6061 aluminum are crucial attributes that ensure the structural integrity of the header and facilitate secure connections, enabling efficient fluid flow throughout the heat exchanger.