In the realm of thermal management, two essential components that often come into play are aluminum heat sink and radiator. These devices are crucial for dissipating heat efficiently, but they serve distinct purposes and operate in different ways. In this blog post, we will delve into the dissimilarities between aluminum heat sinks and radiators, shedding light on their unique characteristics and applications.

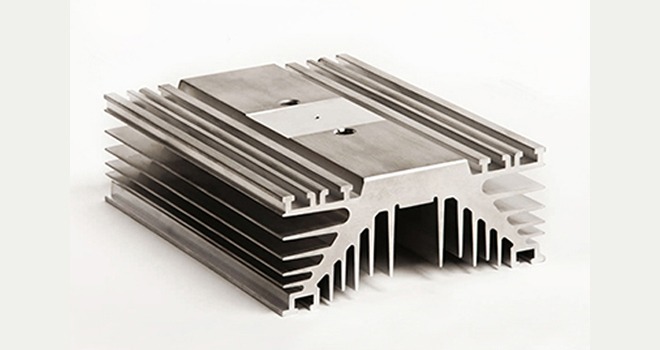

What Is Aluminum Heat Sink

An aluminum heatsink is a passive cooling device used to dissipate heat generated by electronic components like CPUs and GPUs. Typically made of aluminum due to its lightweight nature and good thermal conductivity, heat sinks work by absorbing heat from a hot surface and transferring it to the surrounding environment through increased surface area. This process enhances heat dissipation through convection and radiation. By effectively managing temperature levels, aluminum heat sinks help prevent overheating and maintain the optimal operating conditions of electronic devices. Their cost-effectiveness, lightweight design, and efficient heat transfer capabilities make them indispensable components in various applications requiring thermal management.

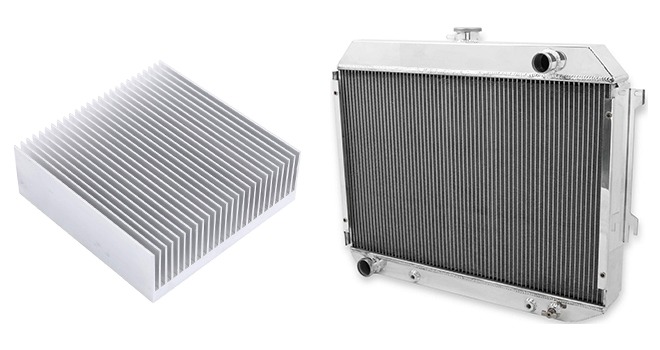

What Is Aluminum Radiators

Aluminum radiators are key components in cooling systems, commonly found in vehicles, HVAC setups, and industrial machinery. These active cooling devices utilize a fluid, such as water or coolant, to transfer heat away from a system. In a typical automotive cooling system, a radiator receives hot coolant from the engine. The coolant circulates through a network of tubes or fins within the radiator, where heat is dissipated into the air through a combination of conduction and convection. This process helps maintain optimal operating temperatures and prevents overheating. Aluminum radiators are valued for their efficient heat dissipation capabilities, versatility across various systems, and their role in temperature regulation. Their effectiveness in managing substantial thermal loads makes them essential components in applications where efficient heat dissipation is critical.

What's The Different

Although they are both for heat dissipation, aluminum heatsinks and radiators are two distinct entities. They share the utilization of aluminum for its thermal properties, efficient heat dissipation goals, and emphasis on thermal management, yet diverge in aluminum grade, profile type, and usage environments.

Aluminum Grade

Aluminum Heat Sink

Aluminum heatsinks typically utilize aluminum alloys like 6061 or 6063 due to their excellent thermal conductivity and ease of machining. These grades offer a good balance of strength, corrosion resistance, and thermal performance, making them ideal for dissipating heat efficiently in electronic devices.

Aluminum Radiator

Aluminum radiators often feature higher-grade aluminum alloys such as 3003 or 5052 for enhanced durability and corrosion resistance. These alloys are chosen for their ability to withstand the demands of cooling systems, including exposure to coolants and varying temperatures.

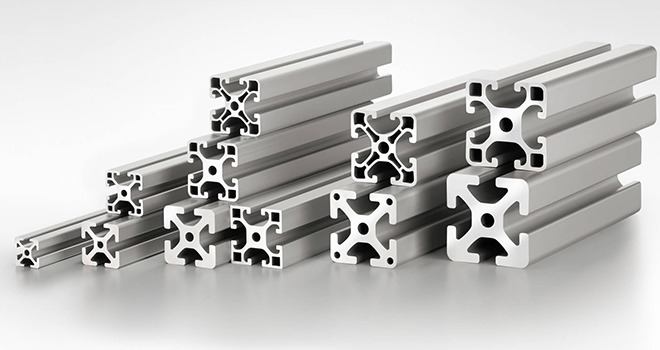

Aluminum Profile Type

Aluminum heat sinks and radiators utilize different aluminum profile types to facilitate heat dissipation effectively. Heatsinks frequently employ extruded or stamped profiles, offering design flexibility and increased surface area for enhanced cooling efficiency.

Aluminum radiators design commonly feature tubes and fins crafted from aluminum. The tubes facilitate coolant circulation, while the fins expand the surface area, aiding in heat dissipation. Both heat sinks and radiators benefit from the use of extruded or brazed aluminum profiles, ensuring optimal heat transfer within their respective systems. Extruded profiles in heat sinks maximize heat transfer surface, while in radiators, they contribute to efficient coolant circulation and heat dissipation. The utilization of specific aluminum profiles tailored to the requirements of heat sinks and radiators underscores the importance of design precision in achieving effective thermal management and heat dissipation in diverse applications.

Using Environment

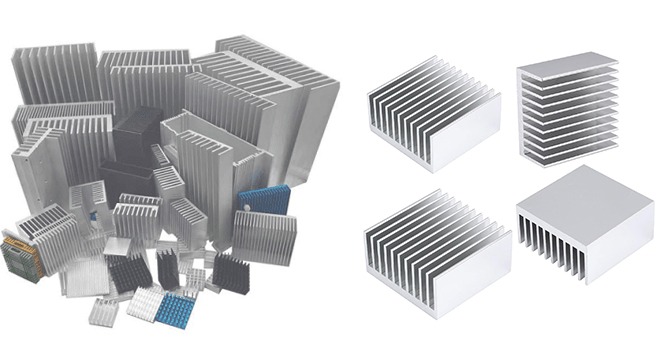

Aluminum Heatsink Applications

Aluminum heat sinks are predominantly used in electronic devices such as computers, LED lights, and power electronics. These devices require effective heat dissipation to prevent overheating and maintain optimal performance. Aluminum heatsinks excel in these environments due to their lightweight nature, corrosion resistance, and thermal conductivity.

Aluminum Radiators Applications

Aluminum radiators are commonly found in automotive cooling systems, HVAC units, and industrial machinery. These systems operate in diverse environments with varying temperatures and exposure to coolant fluids. The radiators are favored for their ability to withstand these conditions while efficiently dissipating heat to regulate temperatures.

Buy High Quality Aluminum Heatsink

Elevate your thermal management solutions with our premium aluminum heat sinks and radiators, crafted by our experienced team of professionals. As a leading aluminum product manufacturer, we take pride in delivering high-quality components that excel in dissipating heat efficiently. Whether you require aluminum heatsinks for electronic devices or aluminum radiators for industrial applications, our products are designed to meet your specific needs with precision and reliability. Reach out to us today to explore our extensive range of aluminum cooling solutions and benefit from our competitive pricing, superior craftsmanship, and dedicated customer service. Trust us to provide you with the best-in-class aluminum heat sinks and radiators that ensure optimal performance and reliability in your thermal management systems.