When it comes to constructing structures or machines that require precise and flexible assembly, extruded aluminum profiles are a popular choice due to their versatility and ease of use. Among the various types of extruded aluminum profiles available, T-slot and V-slot aluminum profiles are two common options that offer distinct advantages for different applications.

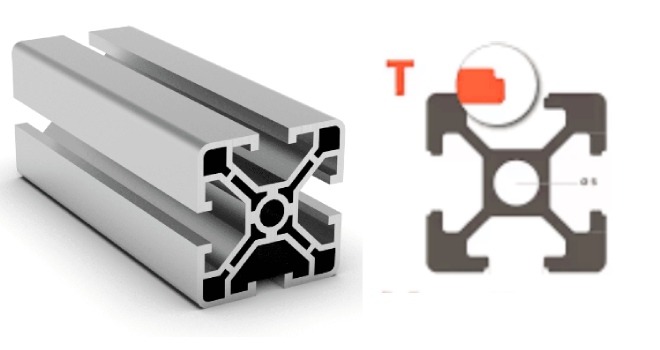

Extruded T Slot Aluminum Overview

Extruded T slot aluminum profiles are known for their T-shaped slot running the length, accommodating T-nuts for easy component securing. This design enables convenient attachment of accessories, components, or fasteners without welding or drilling. Users benefit from swift and flexible assembly adjustments. The versatility of extruded T-slot aluminum profiles makes them ideal for applications requiring easy modification, rapid assembly changes, and secure component placement. These profiles offer a user-friendly solution for projects where adaptability and simplicity in assembly are paramount, providing a reliable and efficient framework for various structures or machines.

The Benefits of Using T-nuts with extruded T Slot Aluminum

Using T-nuts with extruded T-slot aluminum profiles offers several benefits that enhance the versatility and ease of assembly in various projects. Here are some key advantages:

Versatile Attachment: T-nuts allow for the secure attachment of a wide range of components, accessories, or fasteners to the extruded T slot aluminum profiles without the need for additional tools or hardware.

Adjustability: T-nuts can be easily inserted and moved along the T-slot aluminum profiles, enabling users to reposition or add components as needed, facilitating quick and flexible adjustments during assembly.

No Welding or Drilling Required: T-nuts eliminate the need for welding or drilling to attach components to the aluminum profiles, simplifying the assembly process and reducing the risk of damaging the profiles.

Modularity: The use of T-nuts with T-slot aluminum profiles enhances modularity, allowing for easy disassembly and reconfiguration of structures without compromising the integrity of the assembly.

Time and Cost Efficiency: By enabling quick and tool-free assembly, T-nuts help save time and reduce labor costs associated with traditional fastening methods.

Secure Fastening: T-nuts provide a reliable and strong connection between components and the aluminum profiles, ensuring stability and durability in the overall structure.

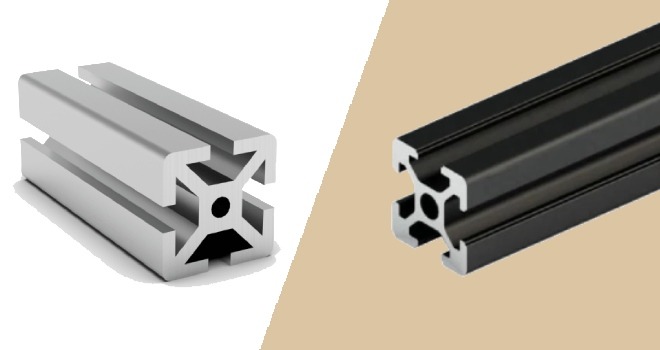

V Slot Aluminum Overview

V-slot aluminum profiles stand out with their hallmark V-shaped groove that spans the length of the material. This unique design imparts exceptional rigidity and stability compared to T-slot counterparts, making V slot aluminum extrusions ideal for applications demanding precise linear motion control. Industries such as 3D printing, CNC machining, and automation systems benefit greatly from the enhanced stability provided by V-slot profiles, ensuring accurate and smooth movement of components. The V-shaped groove allows for secure and precise alignment of parts along the profile, making these profiles a preferred choice for projects where stability, accuracy, and reliable linear motion are paramount considerations in achieving optimal performance.

How V-slot Profiles Enhance 3D Printing Accuracy?

V-slot aluminum extrusions play a crucial role in enhancing 3D printing accuracy by providing several key benefits tailored to the specific requirements of this application:

Linear Motion Precision: The V-shaped groove in v slot aluminum profiles ensures smooth and precise linear motion along the length of the profile. This feature is essential in 3D printing to accurately position the print head and build layers with high precision.

Reduced Play and Tolerance: The rigidity of aluminum extrusion v slot helps minimize play and tolerance issues that can lead to inaccuracies in the final printed object. This results in sharper details, smoother surfaces, and overall improved print quality.

Consistent Movement: The stability provided by aluminum extrusion v slot ensures consistent and reliable movement of the print head and build platform, reducing the chances of deviations or errors during the printing process.

T Slot vs V Slot Aluminum Extrusion

The distinctions between T-slot and V-slot aluminum profile extend beyond their physical shapes, influencing crucial aspects of their functionality and applications.

Assembly and Customization

T slot aluminum extrusion is favored for its versatility in assembly and customization. The T-shaped slot design allows for easy attachment and adjustment of a wide range of connectors and accessories, facilitating swift modifications. In contrast, V-slot aluminum profile, with its V-shaped groove, requires more meticulous positioning of components during assembly, potentially adding complexity to customization processes.

Accessory Compatibility

The T-shaped slot in T slot aluminum extrusion offers extensive compatibility with various accessories and components, providing flexibility and adjustability in design. On the other hand, V-slot aluminum profile is tailored for use with V-slot wheel and linear motion system, limiting its compatibility with other types of accessories. This specialization can be advantageous in applications where precise linear motion is paramount.

Cost Considerations

When comparing T-slot and V-slot aluminum profiles, cost is an important factor to consider. Generally, T slot aluminum extrusions may be more cost-effective due to their widespread use and versatility. The standardized T-slot design allows for easy sourcing of compatible components and accessories, potentially reducing overall project costs. In contrast, the specialized nature of V-slot profiles, especially when considering the need for specific V-slot wheels and linear motion systems, could lead to higher procurement expenses.

Specialized Applications

While T slot aluminum extrusion finds extensive use in a variety of industries such as manufacturing, automation, and robotics due to their versatility and ease of assembly, V-slot aluminum profile is particularly well-suited for specialized applications that demand precise linear motion control. Industries like 3D printing, CNC machining, and automation systems benefit significantly from the unique capabilities of V-slot profiles, allowing for smooth movement and accurate positioning of components within the frame.