In the world of electronics, the enclosure is a vital component that safeguards delicate electronics, ensuring functionality and longevity. Let’s dive into how to select the right aluminum electronics enclosure based on three crucial aspects:

Where to Use Aluminum Electronics Enclosures

Aluminum enclosures are commonly used in a wide range of electronic devices across various industries due to their advantageous properties like lightweight construction, durability, thermal conductivity, and electromagnetic shielding. The initial step prior to selecting aluminum electronics enclosures is to identify the intended application or purpose of the enclosure.

Laptops and Ultrabooks

Aluminum enclosures are popular in laptops and ultrabooks for their lightweight yet robust nature. They provide structural integrity while aiding in heat dissipation, crucial for portable computing devices.

Smartphones and Tablets

Many high-end smartphones and tablets feature aluminum enclosures for their blend of strength, light weight, and sleek appearance. Aluminum helps in dissipating heat efficiently and provides protection against physical damage.

Audio Equipment

Amplifiers, speakers, headphones, and other audio devices often incorporate aluminum enclosures for their electromagnetic shielding properties which help in reducing interference and maintaining signal purity.

Medical Devices

Medical equipment such as patient monitors, diagnostic devices, and portable medical instruments utilize aluminum enclosures for their durability, ease of sterilization, and resistance to corrosion.

LED Lighting Fixtures

Aluminum enclosures are common in LED lighting fixtures due to their excellent heat dissipation properties, which help in maintaining the longevity and performance of the LEDs.

Networking Equipment

Routers, switches, and other networking devices benefit from aluminum enclosures for their thermal conductivity and electromagnetic shielding properties, ensuring reliable operation in networking environments.

Aluminum Electronics Enclosures Types

Aluminum electronics enclosures come in various types, based on the different applications, you need to choose the different types.

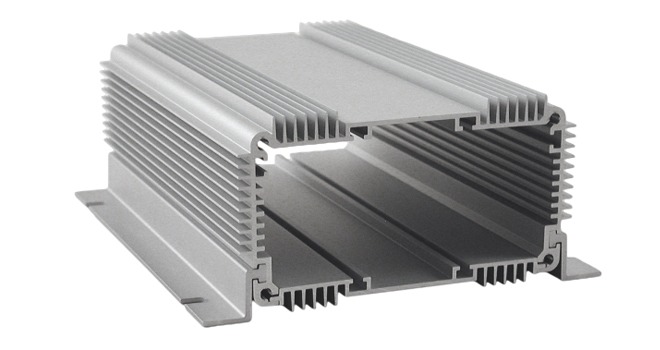

Extruded Aluminum Enclosure

Extruded aluminum enclosures are created by forcing heated aluminum through a die to produce the desired shape. This process allows for the creation of complex and customized enclosure designs with consistent cross-sections.

Extruded Aluminum Enclosures For Electronics

Extruded aluminum enclosures stand out as the optimal housing solution for networking equipment, leveraging their superior thermal conductivity and robust electromagnetic shielding capabilities. These features collectively guarantee a consistent and disturbance-free operational environment essential for networking systems.

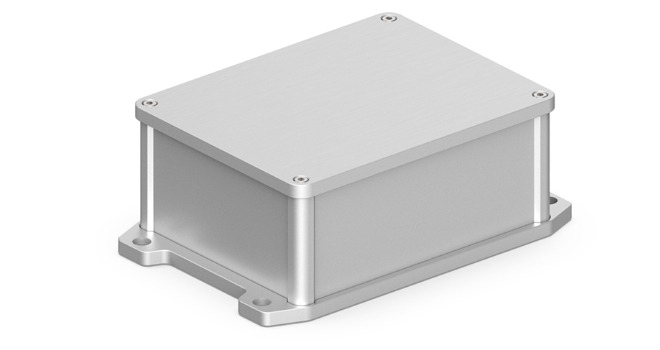

Die Cast Aluminum Enclosure

A die cast aluminum enclosure is a protective casing made through the process of die casting, where molten aluminum is injected into a mold under high pressure to create a solid and precisely shaped enclosure. These enclosures are known for their robustness, durability, and excellent electromagnetic shielding properties. The die-casting process allows for intricate and detailed designs to be produced efficiently, providing a secure and reliable housing solution for electronics that require protection and signal integrity.

Die Cast Aluminum Enclosure Used In Electronic

Die cast aluminum enclosures excel in safeguarding audio equipment due to their exceptional durability, robust construction, and superior electromagnetic shielding capabilities. These features ensure the preservation of signal integrity and purity in audio devices, guaranteeing high-quality sound performance and reliability.

Sheet Metal Aluminum Enclosure

A sheet metal aluminum enclosure is a protective casing typically manufactured by forming and shaping thin sheets of aluminum. These enclosures offer versatility, ease of sterilization, and corrosion resistance, making them well-suited for housing sensitive electronic components in various applications such as medical devices. Sheet metal aluminum electronics enclosures are favored for their ability to maintain hygiene standards, adapt to different designs, and provide a durable housing solution for electronics in medical settings.

Aluminum Enclosures with Heat Sinks

Aluminum enclosures with integrated heat sinks are designed to efficiently dissipate heat generated by electronic components, particularly in applications such as LED lighting fixtures. The combination of the enclosure’s aluminum construction and the heat sink’s thermal management capabilities helps maintain optimal operating temperatures for the enclosed components, ensuring longevity and sustained performance. These specialized enclosures play a crucial role in enhancing the efficiency and reliability of electronic devices, particularly those sensitive to heat buildup.

Waterproof Aluminum Enclosure

Waterproof aluminum enclosures are engineered to provide a protective housing solution for electronic devices, such as high-end smartphones and tablets, in environments where exposure to moisture and dust is a concern. These enclosures combine the lightweight and durable properties of aluminum with waterproofing features to safeguard the enclosed devices against water ingress and dust infiltration. By ensuring a sealed and secure environment, waterproof aluminum electronics enclosures enhance the durability and longevity of electronic devices, making them suitable for use in various challenging conditions while maintaining performance and functionality.

Rackmount Aluminum Enclosure

A rackmount aluminum enclosure is a specialized housing solution designed to accommodate and protect electronic equipment, such as laptops and ultrabooks, in a rack-mounted configuration. These enclosures are constructed from lightweight yet sturdy aluminum materials, offering structural integrity and efficient heat dissipation properties crucial for portable computing devices. The rackmount design allows for easy integration into standard rack systems, making them ideal for applications where space efficiency and mobility are essential, such as data centers or mobile computing setups. Rackmount aluminum enclosures provide a secure and convenient way to house and transport electronics while ensuring optimal performance and reliability.

Choose The Aluminum Grade For Enclosure

Selecting the appropriate aluminum grade is crucial for ensuring the quality and performance of various aluminum electronics enclosures designed for distinct applications.

6061-T6

Aluminum Grade 6061-T6 is distinguished by its exceptional strength, corrosion resistance, and machinability, making it a favored choice for Extruded Aluminum Enclosures that demand efficient heat dissipation capabilities.

A380

In Die Cast Aluminum Enclosures, the application of Aluminum Grade A380 is underpinned by its superior fluidity and mechanical properties, ensuring high strength and dimensional stability essential for rugged enclosure designs.

5052-H32

For Sheet Metal Aluminum Enclosures, the utilization of Aluminum Grade 5052-H32 is justified by its excellent formability, corrosion resistance, and weldability, catering to the specific fabrication requirements and corrosion protection needs of these enclosures.

6063-T5

Aluminum Grade 6063-T5, deployed in Aluminum Electronics Enclosures with Heat Sinks, is recognized for its heat-treatable nature, offering good thermal conductivity and formability critical for efficient heat dissipation within these enclosures.

5083

When it comes to Waterproof Aluminum Enclosures for electronics, the corrosion-resistant and waterproof properties of Aluminum Grade 5083 make it an ideal choice for ensuring protection against moisture and dust infiltration in electronic devices.

6063-T6

Aluminum Grade 6063-T6, selected for Rackmount Aluminum Electronics Enclosures, strikes a delicate balance between strength and formability, enabling the creation of lightweight yet structurally robust enclosures tailored for rackmount configurations.