Aluminum, known for its lightweight and corrosion-resistant properties, is a versatile metal that finds extensive use in various industries. One of the key processes where aluminum shines is in die casting. Die cast aluminum components are integral to many products we use daily, from automotive parts to consumer electronics. In this blog post, we will delve into the world of die cast aluminum, exploring its characteristics, applications, and why it’s a preferred choice in manufacturing.

What Is Die Cast Aluminum?

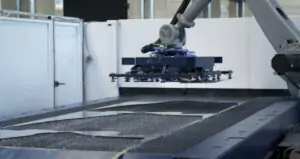

Die cast aluminum refers to aluminum parts and components that are produced using the die casting process. In die casting, molten aluminum is injected into a steel mold under high pressure, allowing for the rapid and precise production of complex shapes with tight tolerances. Die cast aluminum parts are known for their lightweight nature, excellent strength-to-weight ratio, corrosion resistance, and versatility in various industries such as automotive, aerospace, electronics, and consumer goods.

Is Die Cast Aluminum Better Than Regular Aluminum?

In specific situations where complex shapes with tight tolerances are required, die-cast aluminum can offer enhanced strength compared to regular aluminum. The high-pressure die casting process allows for the creation of intricate geometries that may not be easily achievable through traditional aluminum processing methods. Additionally, the denser structure of die-cast aluminum can contribute to improved mechanical properties in applications where strength and durability are critical factors. Conversely, the strength of regular aluminum may prevail in other instances, influenced by factors such as the alloy composition, manufacturing techniques, and the structural design of the component.

Aluminium Grades For Casting

The aluminum grades commonly used for casting, particularly in die casting applications, include:

A380

Known for its good fluidity, pressure tightness, and resistance to hot cracking, A380 is a popular choice for die casting applications. It also boasts good mechanical properties.

A383

Similar to A380 but with enhanced resistance to hot cracking, A383 is suitable for parts exposed to elevated temperatures during processing.

A360

Renowned for its exceptional castability, pressure tightness, and corrosion resistance, A360 finds use in complex die casting applications.

A413

This aluminum alloy offers excellent fluidity, pressure tightness, and resistance to hot cracking, making it versatile for a wide range of die casting applications.

ADC12

Equivalent to the A383 alloy, ADC12 is widely utilized in die casting due to its favorable fluidity, machinability, and corrosion resistance, particularly in the Japanese manufacturing sector.

B390

B390 die cast aluminum features high strength, castability, corrosion resistance, and machinability, making it ideal for automotive and electronics applications requiring durability and precision.

Die Cast Aluminum Performance

Aluminium Grades For Casting | Corrosion Resistance | Resistance to Hot Cracking | Anodizing | Machinability |

A380 | Fair | Very Good | Good | Good |

A383 | Good | Excellent | Good | Very Good |

A360 | Excellent | Excellent | Good | Good |

A413 | Excellent | Good | Good | Fair |

B390 | Fair | Good | Fair | Fair |

What Is The Best Aluminum Alloy for Die Casting?

Alloy A380 (ANSI/AA A380.0) stands out as the most extensively aluminium grades for casting, presenting a superior blend of material characteristics and manufacturing simplicity. It is a preferred choice for a wide range of product applications.

Which Alloy Grade Is Suitable For Your Project?

Various die-cast aluminum grades possess distinct properties that render them suitable for specific projects. These differences in characteristics allow for tailored selections based on the requirements of each unique project, ensuring optimal performance and functionality.

Die Cast Aluminum Applications

Aluminum die castings find extensive applications across diverse industries:

Automotive Industry

The automotive sector heavily relies on aluminum die castings due to the imperative for lightweight, efficient vehicles. Aluminum components are pivotal in enhancing fuel economy, longevity, repairability, and emission control.

Construction Sector

Aluminum die casting plays a growing role in construction, offering electrical conductivity and heat flow advantages. Modern technologies have expanded its use beyond traditional applications like window frames and lighting fixtures.

Electronics Field

Aluminum die-cast parts play a crucial role in modern electronics, serving as lightweight, durable solutions for heat dissipation, electric housing, and structural integrity. From smartphones to household appliances like washing machines, aluminum components are ubiquitous in various electronic devices.

Energy and Mining

Aluminum die castings feature prominently in wind energy equipment and lightweight mining tools. These parts offer durability and electrical conductivity critical for energy generation and mining operations.

Aerospace Industry

Aerospace applications demand lightweight, corrosion-resistant components, making aluminum die castings indispensable. Aircraft components, including propellers, benefit from the strength and reliability of aluminum parts.

Which Cast Aluminum Grades Are Suitable For Your Project?

Various die-cast aluminum grades exhibit unique properties tailored for specific applications:

A380: Widely used in automotive applications for its balanced strength, castability, and corrosion resistance, making it ideal for engine components.

A360: Known for excellent castability and corrosion resistance, suitable for intricate parts like instrument cases and irrigation system components.

A383: Offers good strength and superior castability, commonly used for structural parts in engines and appliances.

A413: With excellent strength and castability, it finds applications in intricate parts like dental equipment and street lamp housings.

B390: Suited for internal combustion engine parts due to its fair strength and castability, commonly used in pistons and cylinder heads.