Aluminum profile bending is a fundamental skill in modern fabrication. From sleek architectural designs to industrial applications, the art of bending aluminum profiles opens up a world of creative possibilities.

Aluminum Profile Bending Considerations

Bending aluminum profiles demands attention to detail. Material choice, timing of treatments, and profile design significantly impact the process.

Material Selection

Alloy choice is pivotal for bendability. Alloys like those from the 6XXX series, though challenging, offer versatility and widespread application in bending applications.

When To Bend Aluminum Profile?

Temper treatments enhance alloy properties. Applying treatments post-bending reduces costs and complexity, ensuring the final product meets specifications efficiently.

Profile Design Optimization

Enhancing profile geometry, maintaining uniform wall thickness, and minimizing size all contribute to improving the quality of curved aluminum extrusions.

Types of Profiles

Aluminum profiles can vary in form, including sheet, rod, or pipe. Each profile type presents unique challenges and opportunities for bending, requiring tailored approaches for successful fabrication.

How To Bend Aluminum?

There exist various conventional techniques for bending extruded aluminum, broadly classified into six primary methods:

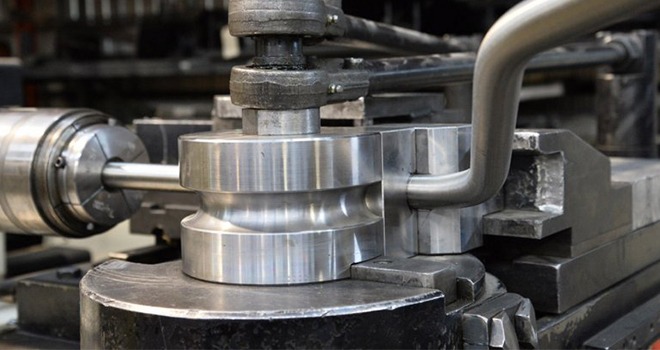

Roller Bending

Roller Bending stands out as a prevalent method for curving extended aluminum extrusions with precision. Renowned for its cost-efficient tooling, this technique excels in crafting fully rounded components. It is especially advantageous for projects requiring moderate production scales and for prototyping endeavors.

Roller Bending Step

Set up the Aluminium Bending Machine:

- Adjust the position of the bottom rollers based on the profile size.

- Ensure that the top roller is properly aligned above the bottom rollers.

Feed the Aluminum Profile:

- Place the aluminum profile horizontally between the bottom rollers.

Adjust Roller Positions:

- Move the bottom rollers to support the profile along its length.

- Adjust the top roller to the desired bending radius.

Start Bending:

- Turn on the roller bending machine.

- Slowly feed the aluminum profile through the rollers.

Monitor the Bending:

- Ensure that the profile is bending smoothly without any deformations or cracks.

Adjust as Necessary:

- If needed, make minor adjustments to the roller positions or bending radius during the process.

Ram Bending

Ram Bending is a cost-effective and straightforward technique known for its ability to bend extrusions precisely to desired angles. However, compared to other methods, it has a higher likelihood of causing profile deformation. Despite its simplicity and accuracy in achieving specific angles, the risk of profile distortion distinguishes this method. While offering affordability and ease of use, practitioners must exercise caution to prevent unintended alterations to the extrusion’s shape during the bending process.

Rotary Draw Bending

Rotary Draw Bending is a sophisticated technique that entails securing and drawing the extrusion around a rotating bending die. Renowned for its ability to achieve remarkably precise angles, this method excels in shaping larger-sized extrusion profiles and accommodating multiple bends within a single part. By leveraging the rotational motion of the bending die, Rotary Draw Bending ensures intricate bends with high accuracy. Its versatility allows for handling diverse profile sizes and executing complex bending sequences efficiently. This method’s precision, coupled with its capability to manage substantial extrusions and intricate bending configurations, makes it an optimal choice for various fabrication requirements.

Compression Bending

Compression Bending employs a compression die to encase the extrusion around a stationary bending die, facilitating a rapid and cost-efficient process suitable for high-volume production requirements. Despite its speed and economic benefits, this method provides minimal support to the profile during bending, increasing the risk of potential deformation. While advantageous for scaling up production due to its efficiency, the lack of comprehensive profile support distinguishes Compression Bending. Practitioners must be mindful of the possibility of deformation inherent in this technique, balancing the benefits of speed and cost-effectiveness with the need for precision in the aluminum profile bending process.

Stretch Bending

Stretch Bending, alternatively referred to as tensile bending, excels in shaping desired forms with minimal distortion through the consistent application of tension. This method is tailored for larger bend radii and creating dynamic shapes on substantial workpieces.

Free-Form Bending

Free-Form Bending is an advanced CNC process that utilizes an articulating ceramic die to create a diverse range of intricate custom bends. While less prevalent, this technique has the potential to shape various extrusion profiles into distinctive and unique products.

What Is The Best Way To Bend Aluminum?

The best way to bend aluminum depends on the specific type of aluminum profile being used. Here are some suitable aluminum profile bending methods for aluminum sheet, aluminum rod, and aluminum pipe:

Aluminum Sheet Bending Method

- Roller Bending: Ideal for bending aluminum sheets due to its ability to handle flat surfaces efficiently.

- Press Brake Bending: Commonly used for precise bends in aluminum sheets, especially for creating sharp angles and bends.

- Stretch Bending: Effective for larger bend radii on aluminum sheets, offering minimal distortion during bending.

Aluminum Tube Bending Method

- Rotary Draw Bending: Well-suited for bending aluminum tubes, offering precise angles and the ability to handle larger-sized profiles and multiple bends.

- Compression Bending: Useful for quick and cost-effective bending of aluminum tubes in high-volume production scenarios.

- Free-Form Bending: Advanced CNC technique suitable for creating complex custom bends on aluminum tubes, especially for unique and intricate shapes.

Aluminum Rod Bending Method

- Roller Bending: Suitable for bending aluminum rods with consistent curvature requirements.

- Hot Bending: Effective for shaping aluminum rods with complex curves, utilizing heat to make the material more pliable.

- Mandrel Bending: Ideal for bending aluminum rods without deforming the interior diameter, providing a smooth bend.