Aluminum alloys play a crucial role in various industries due to their remarkable properties. Among these alloys, aluminum 5083 stands out for its excellent characteristics and wide range of applications. Let’s delve into the properties and applications of 5083 aluminum in this blog post.

Properties Of Aluminum 5083

Aluminum 5083 possesses distinct characteristics encompassing its chemical composition, mechanical attributes, and physical properties.

5083 Aluminum Chemical Compositon

Silicon (Si) | Iron (Fe) | Copper (Cu) | Manganese (Mn) | Magnesium (Mg) | Zinc (Zn) | Titanium (Ti) | Chromium (Cr) | Aluminum (Al) |

0.4% | 0.4% | 0.1% | 0.4-1.0% | 4.0-4.9% | 0.25% | 0.15% | 0.05-0.25% | Balance |

The composition of Aluminum 5083 offers several advantages, including:

Corrosion Resistance: The presence of magnesium and chromium enhances the corrosion resistance of Aluminum 5083, making it suitable for marine applications.

Weldability: This composition enables good weldability, allowing for the fabrication of complex structures with ease.

High Strength: The combination of magnesium and manganese provides Aluminum 5083 with high strength, making it ideal for structural applications.

Formability: The composition facilitates good formability, allowing for shaping and forming into various designs without compromising structural integrity.

Heat Treatment: Aluminum 5083 can be easily heat treated to further enhance its mechanical properties, offering versatility in different applications.

5083 Aluminum Mechanical Properties

The mechanical properties of aluminum 5083 are subject to variation influenced by factors such as thickness and temper. Aluminum 5083 is available in thicknesses ranging from 0.2 to 120mm, with key tempers including 0 (Annealed wrought alloy), H111 (featuring some work hardening from shaping processes, albeit less than that of an H11 temper), and H32 (work hardened and stabilized with a quarter hard temper).

5083 Aluminum: 0.2 - 6.3mm Thickness, O/H111 Temper Mechanical Properties

Property | Value |

Tensile Strength / Mpa | 275 – 350 |

Hardness Brinell / HB | 75 |

Proof Stress / Min Mpa | 125 |

The mechanical properties of 5083 Aluminum with a thickness of 0.2 – 6.3mm under the O/H111 temper exhibit the following features:

High Proof Stress: The minimum proof stress of 125 MPa indicates the material’s ability to resist deformation under load.

Varied Tensile Strength: With a tensile strength ranging from 275 to 350 MPa, this aluminum alloy offers a balance between strength and ductility for diverse applications.

Moderate Hardness: The Brinell hardness of 75 HB suggests a moderate level of surface hardness, suitable for many structural and forming processes.

5083 Aluminum: 6.3 - 80mm Thickness, O/H111 Temper Mechanical Properties

Property | Value |

Tensile Strength / Mpa | 270 – 345 |

Hardness Brinell / HB | 75 |

Proof Stress ./ Min Mpa | 115 |

These properties indicate a similar profile to the thinner variant, with slightly lower minimum proof stress and tensile strength values while maintaining the same Brinell hardness.

5083 Aluminum: 80 - 120mm Thickness, O/H111 Temper Mechanical Properties

Property | Value |

Tensile Strength / Min Mpa | 260 |

Hardness Brinell / HB | 70 |

Proof Stress / Min Mpa | 110 |

Elongation A / Min % | 12 |

These properties indicate a trend of decreasing strength and hardness with increasing thickness, while maintaining a minimum elongation requirement for ductility.

5083 Aluminum: 0.2 - 6.0mm Thickness, H32 Temper Mechanical Properties

Property | Value |

Tensile Strength / Mpa | 305 – 380 |

Hardness Brinell / HB | 89 |

Proof Stress / Min Mpa | 215 |

These properties suggest higher strength and hardness levels compared to the O/H111 temper, making this alloy suitable for applications requiring increased mechanical performance.

Physical Properties Of Aluminum 5083

Property | Value |

Density (kg/m3) | 2650 |

Modulus of Elasticity / Gpa | 72 |

Electrical Resistivity / Ω.m | 0.58 x 10-6 |

Melting Point / °C | 570 |

Thermal Conductivity (W/m.K) | 121 |

Thermal Expansion / K | 25 x 10-6 |

The physical properties of Aluminum 5083 reflect key features of the material:

Density (2650 kg/m³)

The density influences the weight of structures made from Aluminum 5083, making it lightweight yet strong, suitable for applications where weight is a concern, such as in aerospace or marine industries.

Melting Point (570°C)

The high melting point indicates that Aluminum 5083 can withstand elevated temperatures, making it suitable for applications requiring heat resistance, like in engine components or high-temperature environments.

Modulus of Elasticity (72 GPa)

The high modulus of elasticity signifies that Aluminum 5083 is stiff and exhibits good elastic properties, making it suitable for applications where rigidity and strength are crucial, such as in structural components.

Electrical Resistivity (0.58 x 10^-6 Ω·m)

The low electrical resistivity indicates that Aluminum 5083 is a good conductor of electricity, making it suitable for electrical applications where conductivity is essential, like in electrical wiring or components.

Thermal Conductivity (121 W/m·K)

The high thermal conductivity suggests that Aluminum 5083 can efficiently transfer heat, making it suitable for applications where heat dissipation is critical, such as in heat sinks or cooling systems.

Thermal Expansion (25 x 10^-6/K)

The moderate thermal expansion coefficient indicates that Aluminum 5083 expands and contracts moderately with temperature changes, making it suitable for applications where dimensional stability is important across varying temperatures.

Applications Of Aluminum 5083

Aluminum 5083, known for its exceptional properties, finds versatile applications across various industries. Let’s explore how this singular material is utilized in different sectors:

Marine Industry

- Boat Hull: As a marine grade aluminum, aluminum 5083’s corrosion resistance due to magnesium and chromium makes it ideal for boat hulls, ensuring durability in marine environments.

- Offshore Structure: Its high strength and weldability make it suitable for offshore platforms and structures that require resistance to saltwater corrosion

Aerospace Sector

- Aircraft Component: Aluminum 5083’s lightweight nature, combined with its high strength from magnesium and manganese, makes it suitable for aircraft components where weight savings are crucial.

- Aerospace Structure: Its heat-treatable properties allow for enhanced mechanical properties, making it ideal for structural applications in the aerospace industry.

Automotive Manufacturing

- Vehicle Body Panel: The combination of high strength and formability in Aluminum 5083 makes it suitable for vehicle body panels, providing both durability and design flexibility.

- Automotive Frame: Its weldability and resistance to corrosion make it a preferred material for automotive frames where strength and longevity are essential.

Industrial Equipment

- Heat Exchanger: Aluminum 5083’s heat-treatable properties and corrosion resistance make it suitable for heat exchangers in industrial settings, ensuring efficient heat transfer.

- Piping System: Its formability and resistance to corrosion make it ideal for piping systems where durability and reliability are critical.

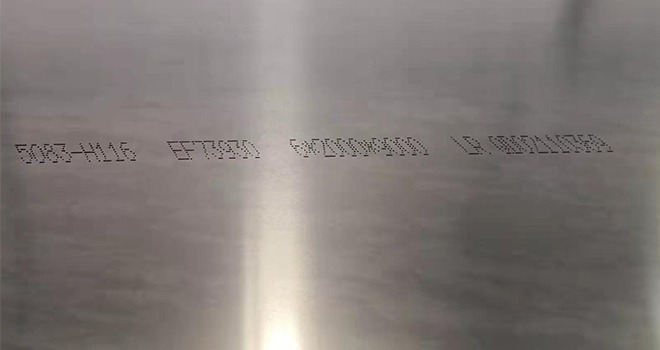

5083 Aluminum Products

With its exceptional properties, Aluminum 5083 lends itself to the creation of a diverse range of aluminum products tailored for a multitude of applications. As a proficient manufacturer of aluminum goods, we offer a comprehensive selection of 5083 aluminum products, encompassing 5083 aluminum sheets, plates, coils, rods, profiles, and more. Reach out to us today for competitive pricing and top-quality solutions.