Aluminum is a versatile material widely used in various industries for its lightweight, corrosion-resistant, and high-strength properties. Among the different types of aluminum alloys available, 6061 and 6063 are two popular choices with distinct characteristics. In this blog post, we will delve into the differences between 6061 and 6063 aluminum to help you understand which one might be the right choice for your project.

6061 Aluminum Overview

6061 Aluminum, known as “structural aluminum,” is a widely used alloy. It belongs to the 6000 series aluminum, featuring magnesium and silicon for enhanced strength and lower melting point.

To be classified as 6061, magnesium content should range between 0.8% to 1.2%, and silicon between 0.4% to 0.8%.

Designers utilize 6061 in various applications due to its well-rounded physical properties, from structural components to aerospace engineering and sports equipment.

This alloy offers decent corrosion resistance, weldability, and tensile strength. Heat treatment can further enhance its strength through artificial aging. Its excellent workability and machinability make it a preferred choice for extruded products.

Compared to specialized aluminum alloys, 6061 is widely available and cost-effective. While not topping physical property charts, its versatility and ease of fabrication in metal-forming processes remain unmatched.

Common Applications of 6061 Aluminum in Aerospace

Aircraft Structures: 6061 is employed in various structural components of aircraft, such as wings, fuselage frames, and landing gear parts, where its strength and durability are crucial.

Satellite Components: Due to its lightweight characteristics and resistance to corrosion, 6061 is utilized in satellite structures and components.

Spacecraft Construction: The alloy is used in the construction of spacecraft due to its combination of strength and weldability, making it suitable for a range of components.

Propulsion Systems: Components of propulsion systems, such as rocket casings and engine parts, benefit from 6061’s strength and heat resistance.

Avionics and Instrumentation: 6061 Aluminum is used in various avionics and instrumentation housings and structures within aircraft for its machinability and protective qualities.

Aerospace Tooling: The alloy is employed in the fabrication of tooling and fixtures necessary for aerospace manufacturing processes due to its workability and durability.

Heat Exchangers: 6061 is utilized in the construction of heat exchangers and cooling systems within aircraft and spacecraft due to its thermal conductivity and corrosion resistance.

6063 Aluminum Overview

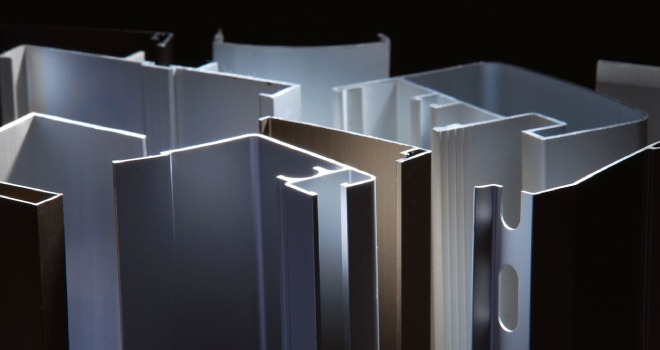

6063 Aluminum, often known as “architectural aluminum,” is specifically designed for easy extrusion, offering a surface that can be readily anodized. Belonging to the 6000 series like 6061, it primarily consists of magnesium and silicon, although in slightly lower proportions. To be classified as 6063, it should contain magnesium within 0.45% to 0.9% and silicon within 0.2% to 0.6%.

While sharing similarities with 6061, 6063 stands out with its excellent corrosion resistance, especially when given a suitable surface finish. It is known for its good weldability, brazeability, and workability, along with moderate tensile strength and decent machinability.

Widely used in extrusion applications, 6063 is favored in architectural, recreational, and furniture industries, particularly in settings where exposure to weather or water is anticipated due to its superior resistance to corrosion compared to 6061.

Common Applications of 6063 Aluminum in Construction

6063 aluminum, also known as “architectural aluminum,” is widely used in the construction industry for various applications due to its specific properties. Some common uses of 6063 aluminum in construction include:

Architectural Extrusions: 6063 aluminum is extensively used for architectural extrusions in building facades, curtain walls, window frames, and door frames due to its extrudability and ability to provide clean and modern aesthetics.

Handrails and Balustrades: The alloy is commonly used for handrails, balustrades, and guardrails in buildings and structures due to its corrosion resistance, durability, and ability to be easily shaped into desired profiles.

Skylights and Canopies: 6063 aluminum is utilized in the construction of skylights, canopies, and sunshades due to its lightweight nature, resistance to corrosion, and suitability for creating sleek and contemporary designs.

Structural Components: The alloy is employed for various structural components in construction, such as beams, columns, and trusses, where its strength-to-weight ratio and durability are beneficial.

Roofing Systems: 6063 aluminum is used in roofing systems and roofing accessories like gutters, downspouts, and flashing due to its corrosion resistance and ability to withstand exposure to weather elements.

Sustainable Building Materials: Given its recyclability and sustainability, 6063 aluminum is favored as a green building material for eco-friendly construction practices.

The Difference Between 6061 And 6063 Aluminum

6061 vs 6063 Strength

The tensile strength difference between 6061 and 6063 aluminum is significant and can impact the structural integrity and load-bearing capacity of components. Aluminum alloy 6061 typically offers medium-to-high tensile strength, ranging from 241 MPa to 310 MPa, depending on the temper treatment applied. On the other hand, alloy 6063 generally provides medium tensile strength, varying between 186 MPa and 290 MPa. This variation in strength levels can influence the suitability of these alloys for different applications in terms of structural stability and performance under load.

6061 vs 6063 Mechanical Properties

When comparing the mechanical properties of 6061 and 6063 aluminum alloys:

6061 Aluminum Mechanical Properties

- Workability: Good workability, making it suitable for forming processes.

- Weldability: Exhibits good weldability, allowing for ease of joining with other materials.

- Brazeability: It has good brazeability, enabling the use of brazing as a joining method.

- Machinability: Offers good machinability, making it suitable for CNC machining operations.

- Electrical Resistance: Features a low electrical resistance ranging from 0.0365 to 0.043 Ω·mm²/m.

- Thermal Conductivity: Demonstrates a relatively high thermal conductivity of 154 to 180 Wm⁻¹K⁻¹.

6063 Aluminum Mechanical Properties

- Workability: Good workability, allowing for ease of shaping and forming.

- Weldability: Shows good weldability properties for joining processes.

- Brazeability: Offers good brazeability, facilitating the use of brazing techniques.

- Machinability: Provides fair machinability for various machining operations.

- Electrical Resistance: Features a somewhat lower electrical resistance of 0.035 Ω·mm²/m compared to aluminum alloy 6061.

- Thermal Conductivity: Exhibits a somewhat higher thermal conductivity ranging from 200 to 209 Wm⁻¹K⁻¹ compared to 6061.

These distinctive mechanical properties dictate the appropriateness of each alloy for specific industrial applications, based on factors like formability, welding capabilities, machining requirements, as well as electrical and thermal conductivity needs.

Which Aluminum Should You Choose?

Selecting the appropriate aluminum alloy—be it 6061 or 6063—depends on the specific requirements of your application. Both alloys can be shaped using a variety of aluminum-forming techniques, yielding satisfactory product properties. Your project particulars will play a crucial role in determining which alloy is better suited for your intended applications.

Aluminum alloy 6061, the second most favored aluminum alloy for extrusions, offers a marginally better strength-to-weight ratio compared to 6063. With commendable machinability and weldability, it is a versatile alloy suitable for a wide range of applications. Opt for 6061 when prioritizing strength over corrosion resistance.

On the other hand, alloy 6063 reigns as the most popular aluminum alloy for extrusions. Notable for its slightly superior corrosion resistance and visually appealing surface finish ideal for anodizing, it is preferred for applications where sufficient strength is required alongside enhanced corrosion resistance.