Aluminum is a versatile metal with a wide range of applications across various industries. One of the popular aluminum alloys is 5052 aluminum, known for its excellent corrosion resistance, formability, and weldability. In this comprehensive guide, we will delve into the properties, applications, and uses of 5052 aluminum.

5052 Aluminum Properties

5052 aluminum boasts exceptional corrosion resistance, high formability, and weldability, making it a popular choice for various applications.

5052 Aluminum Denisity

The low density of aluminum 5052, which is approximately 0.098 lb/in³, can be attributed to the elemental composition of the alloy. Aluminum itself is a lightweight metal with a relatively low density, and when combined with other elements in the 5052 alloy such as magnesium and chromium, the resulting material retains this lightweight property. Magnesium, in particular, is a key alloying element in aluminum 5052 that contributes to its strength and corrosion resistance while keeping the overall density low. This combination of elements results in a lightweight yet durable material that is well-suited for applications requiring strength, corrosion resistance, and a reduced weight.

Other Physical Properties Of Aluminum 5052

In addition to its low density, 5052 aluminum exhibits several other notable physical properties:

Melting Point: The melting point of 5052 aluminum typically ranges between 1,125-1,200 °F, making it suitable for various manufacturing processes that involve heating and shaping.

Specific Heat: The specific heat of aluminum 5052 is approximately 2.1 x 10^-1 BTU/lb-°F, indicating the amount of heat required to raise the temperature of one pound of the material by one degree Fahrenheit. This property is important in understanding the material’s thermal behavior and its applications in heat transfer processes.

5052 Aluminum Mechanical Properties

The mechanical and thermal properties of aluminum alloy 5052 play a crucial role in its performance across various applications:

Ultimate Tensile Strength: Alloy 5052 exhibits an ultimate tensile strength of 28 ksi, indicating the maximum stress the material can withstand before failure under tension.

Yield Tensile Strength: With a yield tensile strength of 13 ksi, alloy 5052 shows the stress at which the material begins to deform plastically.

Fatigue Strength: The fatigue strength of 5052 aluminum is 16 ksi, representing its resistance to cyclic loading and potential failure under repeated stress.

Hardness (Brinell): The Brinell hardness of alloy 5052 is 47, indicating its resistance to indentation or penetration.

Elongation at Break Percentage: The material elongates by 22% before reaching its breaking point, showcasing its ductility and ability to deform before failure.

Thermal Conductivity: 5052 aluminum has a thermal conductivity of 960 BTU-in/hr-ft²-°F, indicating its ability to conduct heat efficiently.

Electrical Conductivity: With an electrical conductivity of 35% IACS (International Annealed Copper Standard), 5052 aluminum is a good conductor of electricity.

Hot Sale Temper Of Aluminum Alloy 5052

The hot sale temper of aluminum alloy 5052 is 5052 H32, and 5052-H34, known for their versatile properties. These tempers strike a balance between strength and formability, making them a popular choice for a wide range of applications.

5052 H32 Properties

In the H32 temper, aluminum alloy 5052 presents a lightweight composition of 0.098 lb/in³, ideal for weight-sensitive applications. Its ultimate tensile strength of 33 ksi and yield tensile strength of 28 ksi ensure durability under varying stress levels. The alloy’s fatigue strength of 17 ksi resists cyclic loading, crucial for components enduring repeated stress. With a shear strength of 20 ksi, it shows resilience against shearing forces, while a Rockwell hardness of B17 and Brinell hardness of 60 demonstrate toughness. These properties position 5052 H32 as a reliable choice for applications requiring a balance of strength and formability, commonly found in marine, automotive, and architectural sectors due to its corrosion resistance and weldability.

5052-H34 Properties

In the H34 temper, aluminum alloy 5052 showcases a robust array of properties that highlight its versatility across various applications. With an ultimate tensile strength of 38 ksi and a yield tensile strength of 31 ksi, this alloy embodies durability under diverse stress conditions. Its fatigue strength of 18 ksi ensures resilience against cyclic loading, vital for components enduring repetitive stress. Additionally, a Rockwell hardness of B31 and Brinell hardness of 68 signify its toughness. Combined with a 10% elongation at break and a modulus of elasticity of 10,200 ksi, 5052-H34 emerges as a dependable choice for applications necessitating strength and reliability. The H34 temper offers increased strength compared to H32, making it suitable for applications requiring a touch more robustness. While slightly less formable than 5052 H32, H34 still maintains good formability, allowing for versatile shaping. Similar to H32, 5052- H34 boasts enhanced corrosion resistance, crucial for environments prone to corrosion. This temper is commonly favored for applications demanding a bit more strength without compromising significantly on formability or corrosion resistance.

5052 Aluminum Products

5052 aluminum products are versatile and find applications across various industries, each benefiting from a specific temper to meet specific requirements:

5052 H32 Aluminum Products

5052 Aluminum Angle: The H32 temper of 5052 aluminum angle offers a perfect blend of strength and formability, making it a preferred choice for structural applications that require both robustness and the ability to be shaped and manipulated. Commonly used in construction, architectural frameworks, and fabrication projects where a balance of strength and workability is crucial.

5052 Aluminum Tubing: With the H32 temper, 5052 aluminum tubing provides excellent formability and moderate strength, catering to industries such as marine and automotive where corrosion resistance and workability are paramount. Ideal for applications like fluid transportation, framing, and structural components that demand durability and ease of fabrication.

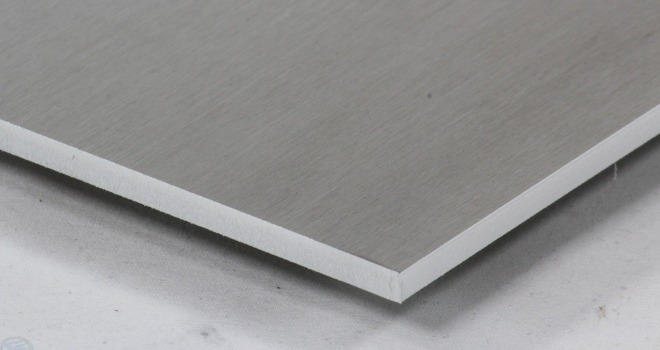

5052 Aluminum Sheet: 5052 H32 aluminum sheet excels in formability and offers moderate strength, making it well-suited for applications like roofing, siding, and general sheet metal work that require shaping. Widely used in architectural cladding, signage, and automotive panels where malleability and strength are essential.

5052 Aluminum Plate: The H32 temper of 5052 aluminum plate strikes a balance between strength and formability, making it suitable for applications requiring flat surfaces with moderate strength. Commonly employed in marine components, structural panels, and industrial equipment where a combination of durability and workability is needed.

5052 Aluminum Rod: 5052 H32 aluminum rods offer good formability and moderate strength, making them ideal for applications where machinability and corrosion resistance are crucial. Widely used in marine hardware, architectural structures, and machinery components where both workability and durability are vital.

5052 H34 Aluminum Products

5052 Aluminum Extrusions: These extrusions in the 5052-H34 temper provide enhanced strength, making them ideal for structural applications where robustness is paramount. Commonly used in industries such as construction, transportation, and aerospace for their ability to withstand heavy loads and structural stresses.

5052 Aluminum Profiles: Profiles made from aluminum 5052 in the H34 temper offer exceptional durability, making them perfect for trim pieces and structural components that require long-lasting performance. Widely utilized in architectural trim, door frames, and furniture where both strength and aesthetics are important.

5052 Aluminum Forgings: Forgings crafted from 5052 aluminum in the H34 temper boast superior mechanical properties, making them well-suited for heavy-duty applications that demand high strength and reliability. Often found in aerospace components, marine hardware, and industrial machinery where exceptional mechanical strength is essential for safe and efficient operation.